TS-NANO SEALANTS PERFORMANCE

Backed by decades of experience in nanomaterial sciences and sub-surface engineering, TS-Nano patented its sealants that provide sealing solutions to site-specific, complex field problems.

TS-NANO SEALANT Does Not Mix With Water

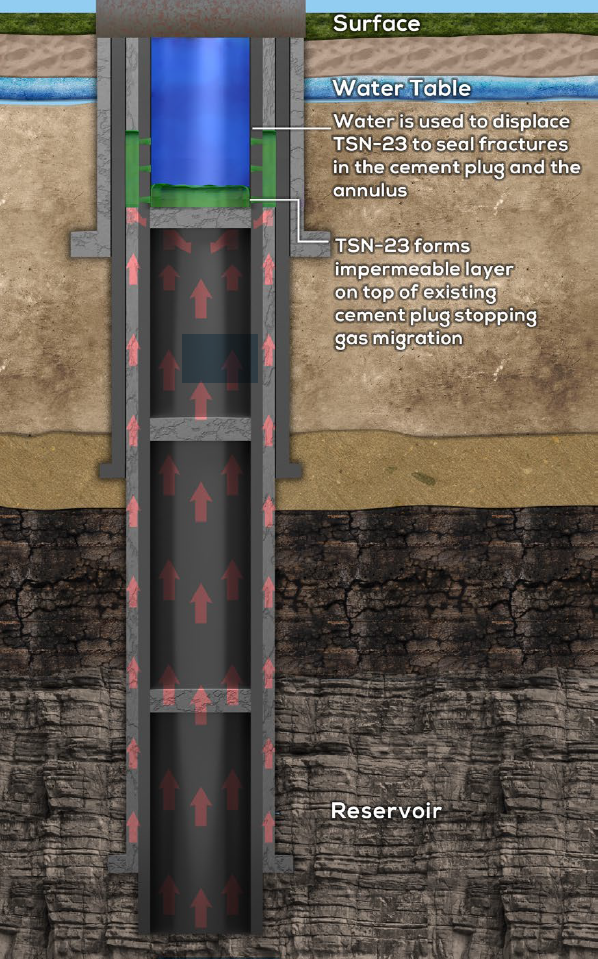

TS-Nano sealant, TSN-25 is designed to be squeezed behind casings by itself. TSN-25 is water-insoluble and heavier than water. The benefit? You can use water to squeeze the sealants into the wellbore.

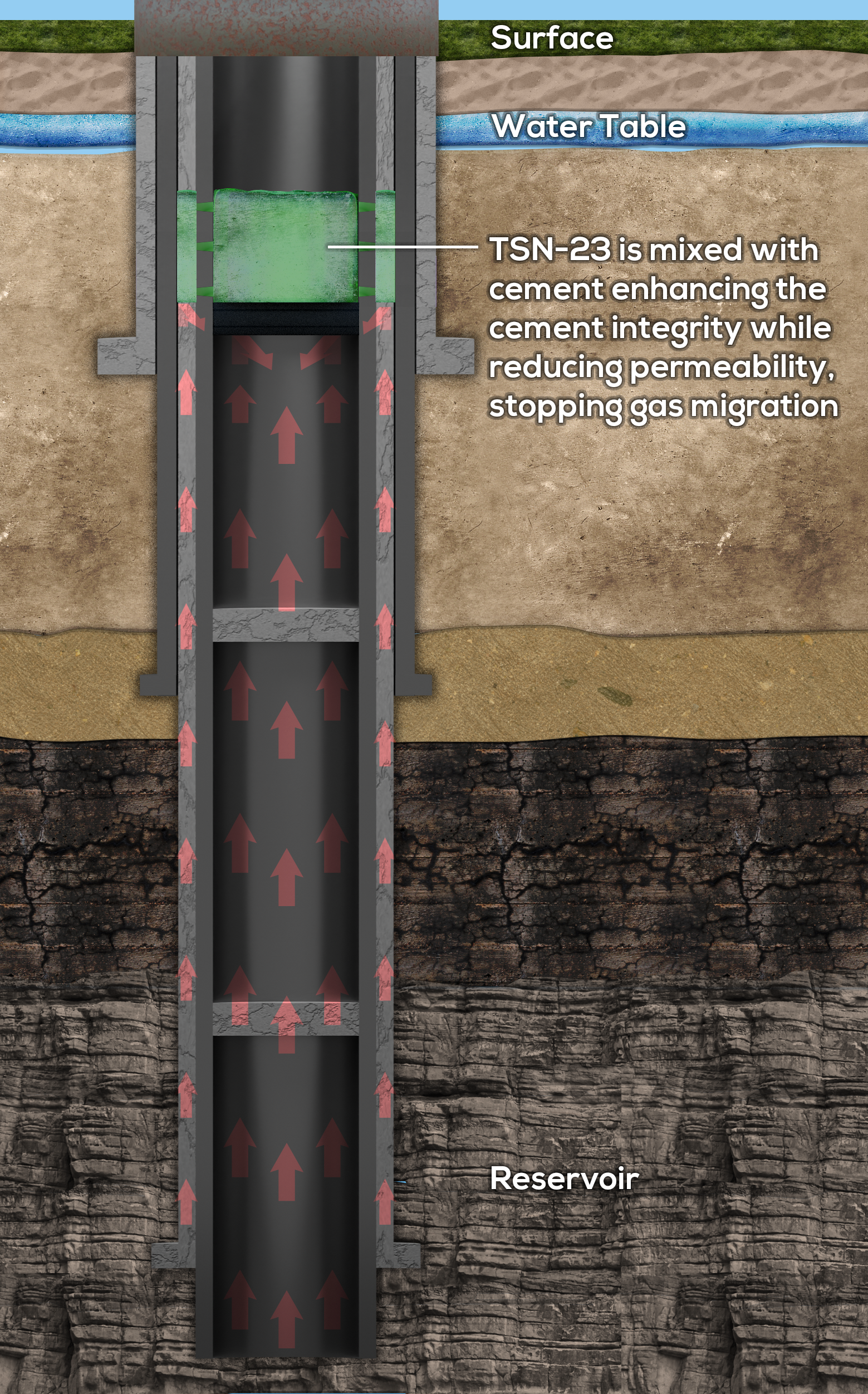

NANO-MODIFIED POLYMER CEMENT

A specially formulated TS-Nano product, TSN-23, can be mixed with cement to produce next-generation slurries with superior sub-surface performance.

Core Features

Field Deployment Cases

Case #1 (NE British Columbia, Canada)

Surface Casing Vent Flow during Well Abandonment

Our client’s well has completed the cement squeeze at the production zones. For abandonment regulatory requirements, our client measured the surface casing vent flow and observed a small quantity of gas flow that did not pass the regulation.

TS-Nano Collaboration

By working with our client, we collectively selected an interval at a shallow caprock formation (below the surface casing shoe) and intended to use TSN-25 as an interceptive sealing agent to block off mirco-annulus and ultra-fine cracks in the cements. The sealant was mixed and deployed by wirleine truck and dump bailer. A portion of the sealant was successfully squeezed behind the production casing. Pressure was kept at the well overnight to help the sealant curing. After four months of our sealant squeeze, our client re-visited the well and found the results satisfactory.

Case #2

Cut Production Casing With Leaking Cement Plug

This Permian Basin well needed to be Plugged and Abandoned due to mechanical issues. The 5.5-inch production casing was cut and pulled just above a leaking cement plug, leaving a 36ft (~11m) open hole section below the surface casing shoe to place a plug.

TS-Nano Solutions

With such a large volume void, the TS-Nano product TSN-23 was mixed with cement, and the modified cement slurry was pumped downhole to the target depth of 400 ft (122 m). The cement plug mixed with the TS-Nano product successfully passed the regulatory test. This operation allows the well owner to continue filling the wellbore with cement to the surface and complete the entire Plug & Abandon operations.

Case #3

Sustained Casing Pressure (Surface Casing Vent Flow)

This Permian Basin well had cement plugs set at various depths throughout the 7-inch production casing. Previous attempts to mitigate the sustained casing pressure were unsuccessful.

TS-Nano Solutions

TS-Nano collaborated with the well owner to identify poor cement bonds between the surface and production casing strings. To eliminate cement shrinkage and improve cement properties, TS-nano nano-modified polymer sealant, TSN-23, was with mixed with the cement and pumped down the wellbore. After the operations, the well sustained casing pressure diminished and the owner was able to P&A in compliance with local regulatory requirements.